Our LUVOCOM 3F materials take account of the process and final product during the design stage and are therefore able to achieve another level of properties and quality. All our products are thoroughly tested in our development laboratory, which ensures that they work in all the systems available on the market.

Below you will find information on our commercially available products, including data sheets and pictures.

Experience with the new

Every week we develop new materials, usually as a customized solution for our clients. This tremendous development speed is made possible by the knowledge and great experience of our employees. Added to this is good collaboration and coordination between our market development, product development department and ultimately our production unit. Our laboratory and our applications technology are also extensively equipped for new developments and contribute to the optimization of the formulations.

Optimum raw materials and near-production-ready samples

When we prepare a new formulation for you, it is adjusted exactly to your application. To achieve this, we select the most suitable raw materials for the application. We are independent of the polymer manufacturers and raw material suppliers and prepare samples in the quantity you require on production equipment.

A glimpse of the future

Our development department is involved in a permanent exchange with research establishments and the development departments of polymer and additive producers. This is because, in addition to the manufacture of individual formulations on behalf our clients, we also anticipate technological developments and trends so that we can adopt a proactive approach by offering solutions for new applications.

LUVOCOM® 3F PAHT 9825 NT (High-Temp. Nylon)

LUVOCOM® 3F filament PAHT 9825 NT is a high temperature resistant polyamide (PA) -based, unfilled material. It has the strength of a PA6 without affecting its printability. LUVOCOM® 3F PAHT 9825 NT is a material from LEHVOSS. 3D-printed components made from this material have high strength and toughness. It has a low influence from moisture and temperature on dimensional stability and electrical properties. Can be used in the automotive industry, textile- and office machinery, apparatus- and precision engineering.

Features

-

Unreinforced PAHT

-

Designed for industrial applications

-

PA6 based material

-

Low warping and increased layer adhesion

-

Strong and tough parts

LUVOCOM® 3F PAHT 9936 BK (High-Temp. Nylon)

LUVOCOM® 3F PAHT 9936 BK is an unreinforced polyamide-based formulation. LUVOCOM® 3F PAHT 9936 BK is a material from LEHVOSS. LUVOCOM® 3F PAHT 9936 BK has excellent tensile and impact strength and allows continued operation up to 100°C – 120°C while retaining 50% of its mechanical properties and short-term 160°C.

Features

-

Unreinforced PAHT

-

Optimized surface appearance

-

Designed for industrial applications

-

PA6 based material

-

Low warping and increased layer adhesion

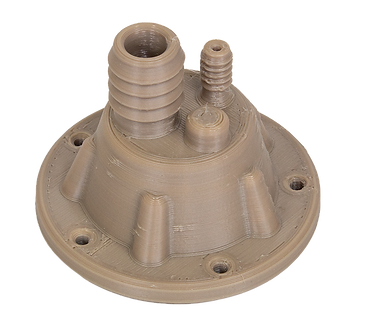

LUVOCOM® 3F PAHT CF 9891 BK (High-Temp. Nylon)

LUVOCOM® 3F PAHT CF 9891 BK is a 15% carbon fiber reinforced material. LUVOCOM® 3F PAHT CF 9891 BK is a material from LEHVOSS. It is designed for industrial applications, easy to print with low warping an increased layer adhesion. LUVOCOM® 3F PAHT CF 9891 BK is a PA6 based material, it has a low influence from moisture and temperature on dimensional stability and electrical properties.

Features

-

Carbon Fiber Reinforced Material (15%)

-

Extremely stiff

-

Designed for industrial applications

-

PA6 based material

-

Low warping and increased layer adhesion

LUVOCOM® 3F PEKK 50082 NT

LUVOCOM® 3F PEKK 50082 NT (Polyether Ketone Ketone) is a semi-crystalline thermoplastic in the polyaryletherketone family. LUVOCOM® 3F PEKK 50082 NT is a material from LEHVOSS. This material has a very good layer adhesion and dimensional stability. LUVOCOM® 3F PEKK 50082 NT is unique compared to the standard PEKK materials because it prints semi crystalline and it provides improved printability and layer adhesion. This neat PEKK enables semi-crystalline parts with no warping.

Features

-

Outstanding temperature and chemical resistance

-

Excellent mechanical properties

-

Flame retardant

-

Unique tribological properties

LUVOCOM® 3F PP CF 9928 BK

LUVOCOM® 3F PP CF 9928 BK is polypropylene copolymer reinforced with carbon fiber. LUVOCOM® 3F PP CF 9928 BK is a material from LEHVOSS. It is suitable for continuous discharging of statically-generated electricity. Recommended for strong and stiff parts.

Features

-

Strong and stiff parts

-

Inherent good chemical resistance

-

ESD surface resistance 107Ω

-

Low warpage

LUVOCOM® 3F PEEK 9581 NT

_edited.png)

LUVOCOM® 3F PEEK 9581 NT is based on polyetheretherketone (PEEK), one of the highest performing engineering thermoplastics in the world and can replace metals and composites. LUVOCOM® 3F PEEK 9581 NT is a material from LEHVOSS. LUVOCOM® 3F PEEK 9581 NT is an unreinforced grade and can be used for multiple applications in different industries; aerospace-, gas-, oil-, automotive- and the medical industry. This semi crystalline thermoplastic provides high temperatures, excellent mechanical and chemical resistance properties. The excellent layer adhesion of LUVOCOM® 3F PEEK 9581 NT improves the impact resistance, strength, durability and the printing process.

Features

-

Outstanding temperature and chemical resistance

-

High strength, including z-layers

-

Flame retardant

-

Cytotoxicity proliferation according EN ISO 10993-1

LUVOCOM® 3F PEEK CF 9676 BK

_edited.png)

LUVOCOM® 3F PEEK CF 9676 BK has outstanding mechanical properties in combination with its excellent thermal and chemical resistance. LUVOCOM® 3F PEEK CF 9676 BK is a material from LEHVOSS. It is a flame retardant polyetheretherketone reinforced with carbon fibers The carbon fiber improves the stiffness and compressive strength enormously This material is suitable for dynamically stressed parts, aerospace applications and applications which require inherent flame resistance.

Features

-

Outstanding temperature and chemical resistance

-

Very high strength and stiffness

-

Suitable for dynamically-stressed parts

-

Flame retardant

-

Low smoke and toxic gas emissions

_edited.png)